Artwork Management System v/s Project Management Tools: Key Differences

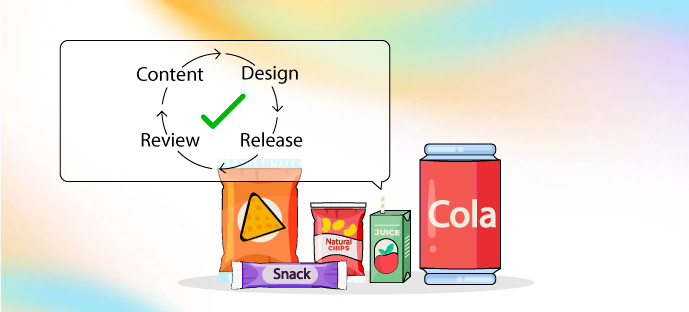

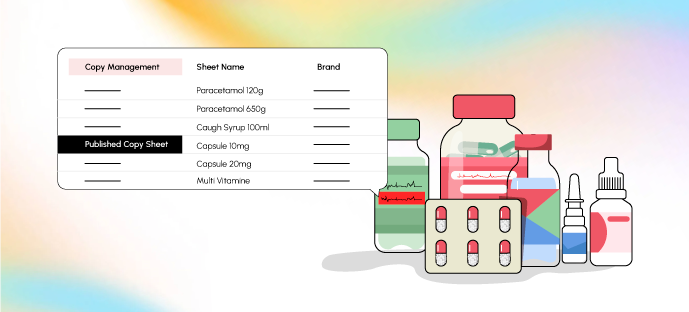

Artwork management system streamlines the entire artwork lifecycle while the offerings of project management tools like task assignment, resource management, and workflow creation are limited when compared to streamlining packaging and labeling processes.